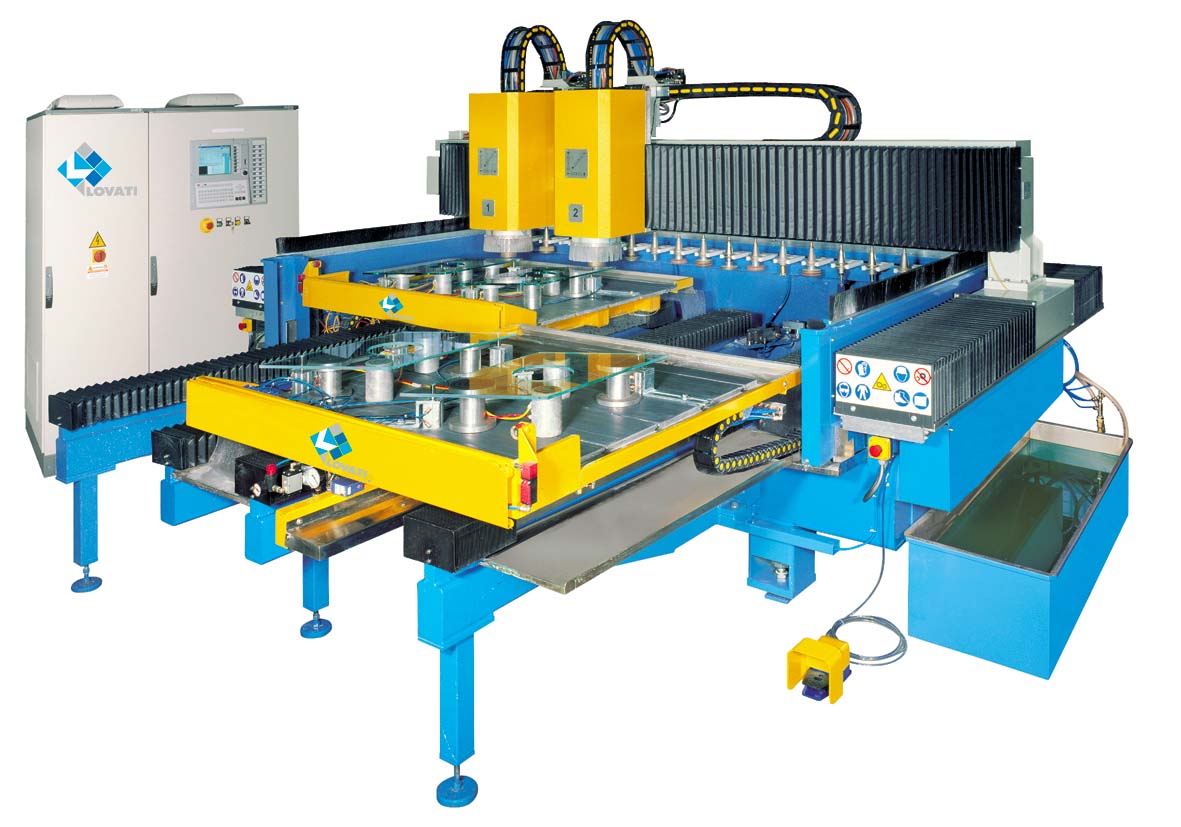

IZAR

Numerical control machine

IZAR is a CNC machine to grind and polish the edge on shaped glasses with internal curves, external curves, straight line sides and corners. It can also make holes, internal and external millings and routings.

LYNX

Numerical control machine

LYNX is a CNC machine to grind and polish the edge on shaped glasses with internal curves, external curves, straight line sides and corners. It can also make holes, internal and external millings and routings.

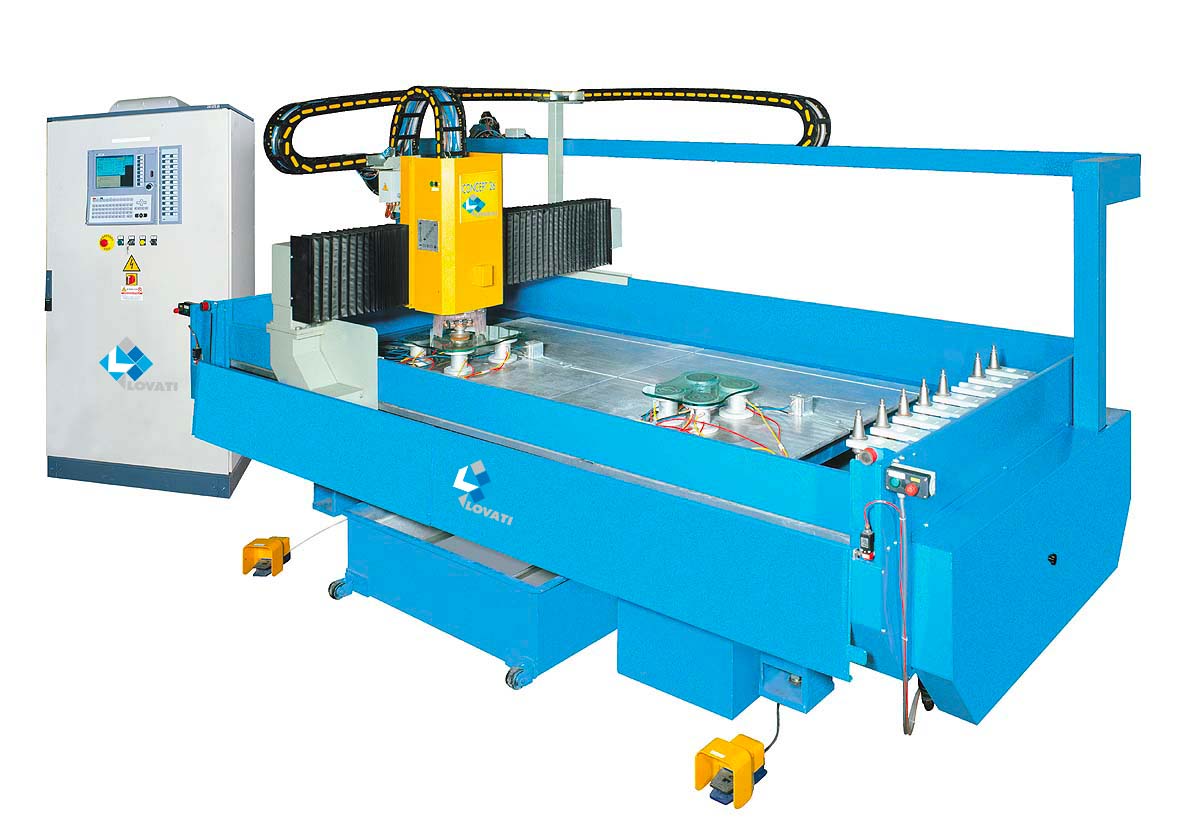

CONCEPT

Numerical control machine

CONCEPT is a CNC machine to grind and polish the edge on shaped glasses with internal curves, external curves, straight line sides and corners. It can also make holes, internal and external millings and routings.

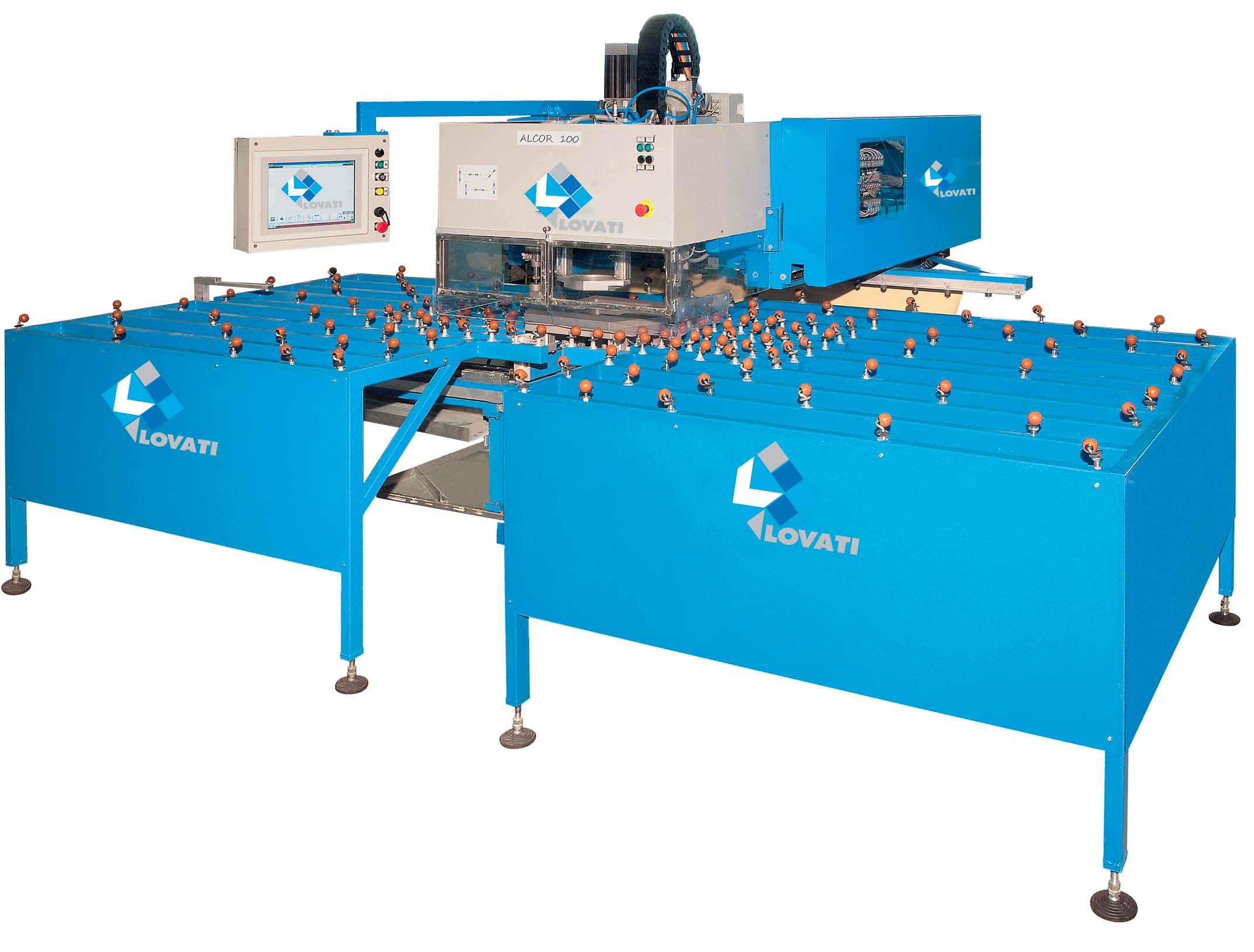

ALCOR

Numerical control machine

ALCOR is a numerical control machine with one double head to perform holes, routings, notches, pins and screw inserts and to grind and polish round and shaped corners.

VELA

Semiautomatic machine

VELA grinds the bevel and the edge on shaped glass with internal curves, external curves, straight-line sides and mitred corners.